A color match guarantee is a key quality assurance step in luxury car repairs, ensuring paint accurately replicates the original color using advanced technology and strict adherence to manufacturer guidelines. Skilled professionals use specialized tools like paint scanners and CAD software for precise measurements, exceeding OEM standards for customer satisfaction. Best practices include obtaining original paint codes, using dedicated equipment, conducting test patches, and considering unique proprietary paint formulations.

In today’s market, a color match guarantee is an essential aspect of ensuring customer satisfaction. This comprehensive guide delves into the intricacies of such guarantees, focusing on compliance with manufacturer specifications. We explore best practices for accurate color matching and provide insights on adhering to supplier guidelines. Understanding these policies is crucial for businesses aiming to deliver exceptional products, fostering brand loyalty, and standing out in a competitive market.

- Understanding Color Match Guarantee Policies

- Ensuring Compliance With Manufacturer Guidelines

- Best Practices for Accurate Color Matching

Understanding Color Match Guarantee Policies

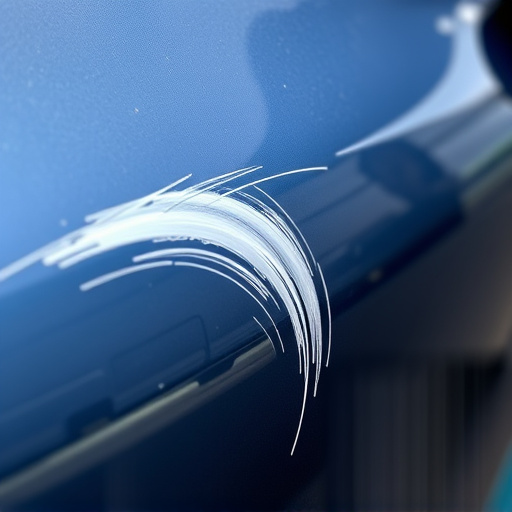

A color match guarantee is a crucial aspect of quality assurance in the automotive industry, particularly for luxury vehicle repairs and collision services. It ensures that when a car undergoes painting or repair, the new paint will precisely replicate the original color of the vehicle. This guarantee addresses the aesthetic integrity of the vehicle, which is paramount for retaining its market value and sleek appearance.

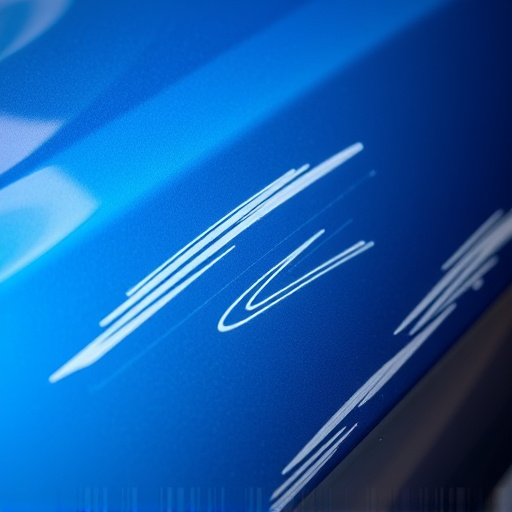

Automotive manufacturers typically specify detailed procedures and standards for achieving an accurate color match. These specifications involve precise mixing of pigments, application techniques, and curing processes. Reputable collision repair shops adhere to these guidelines to deliver top-notch results. The process often involves advanced technology, such as computer-aided color matching systems, ensuring the accuracy of the final product matches the manufacturer’s original standards for a seamless frame straightening and repair experience.

Ensuring Compliance With Manufacturer Guidelines

When offering a color match guarantee, it’s paramount to adhere strictly to manufacturer guidelines and specifications. This involves meticulous attention to detail during the frame straightening or vehicle bodywork restoration process, ensuring that every step aligns with the original equipment manufacturer (OEM) standards. The goal is to maintain the integrity of the vehicle’s appearance, particularly in intricate areas like panel gaps and curves, which are often challenging to match precisely.

Professionals skilled in color matching and vehicle restoration understand the importance of using specialized tools and technologies, such as advanced paint scanners and computer-aided design software. These resources enable accurate measurements and calculations, bridging the gap between the restored or repaired section and the original vehicle bodywork. By staying within these parameters, technicians can confidently deliver a color match that not only meets but exceeds manufacturer expectations, ensuring customer satisfaction in every aspect of the vehicle’s aesthetic restoration.

Best Practices for Accurate Color Matching

To ensure accurate color matching under a color match guarantee, best practices dictate a multi-step process. Begin with obtaining an exact match of the vehicle’s original paint code from the manufacturer. This precise information allows for the closest reproduction possible during the bumper repair or auto body services process. Next, use specialized equipment and tools designed to measure and mix colors precisely, minimizing human error. Professionals in automotive body shops should also conduct multiple test patches before proceeding with the full repair, allowing them to assess and adjust color matching under controlled conditions.

Additionally, considering the unique formulations of different car manufacturers can be crucial. Some brands have proprietary paint blends that may require specific techniques or products to achieve a perfect match. Staying updated on these nuances ensures not only adherence to manufacturer specifications but also delivers the highest quality results in bumper repair and other auto body services.

A successful color match guarantee requires a deep understanding of manufacturer specifications and adherence to best practices. By ensuring compliance with these guidelines, businesses can offer precise color matching, enhancing customer satisfaction and fostering trust. Remember, a robust color match guarantee is not just about meeting standards; it’s about delivering on promises, ensuring visual accuracy, and ultimately, providing a superior product experience.